UNICUT 600

The number one amongst the diesel floor cutters. Fully hydraulic, comfortable, easy to use with joystick control. Developed together with professional users for the most demanding applications.

The 100 kW / 136 PS powerful UNICUT 600 is the flagship diesel floor cutter. Its hydraulically controlled drive is extremely robust even in the toughest of continuous use tasks and, can be operated without restriction under full load, without any significant wear. The fully hydraulic floor saw achieves cutting depths of up to 630 mm with saw blades up to a maximum of 1,500 mm diameter.

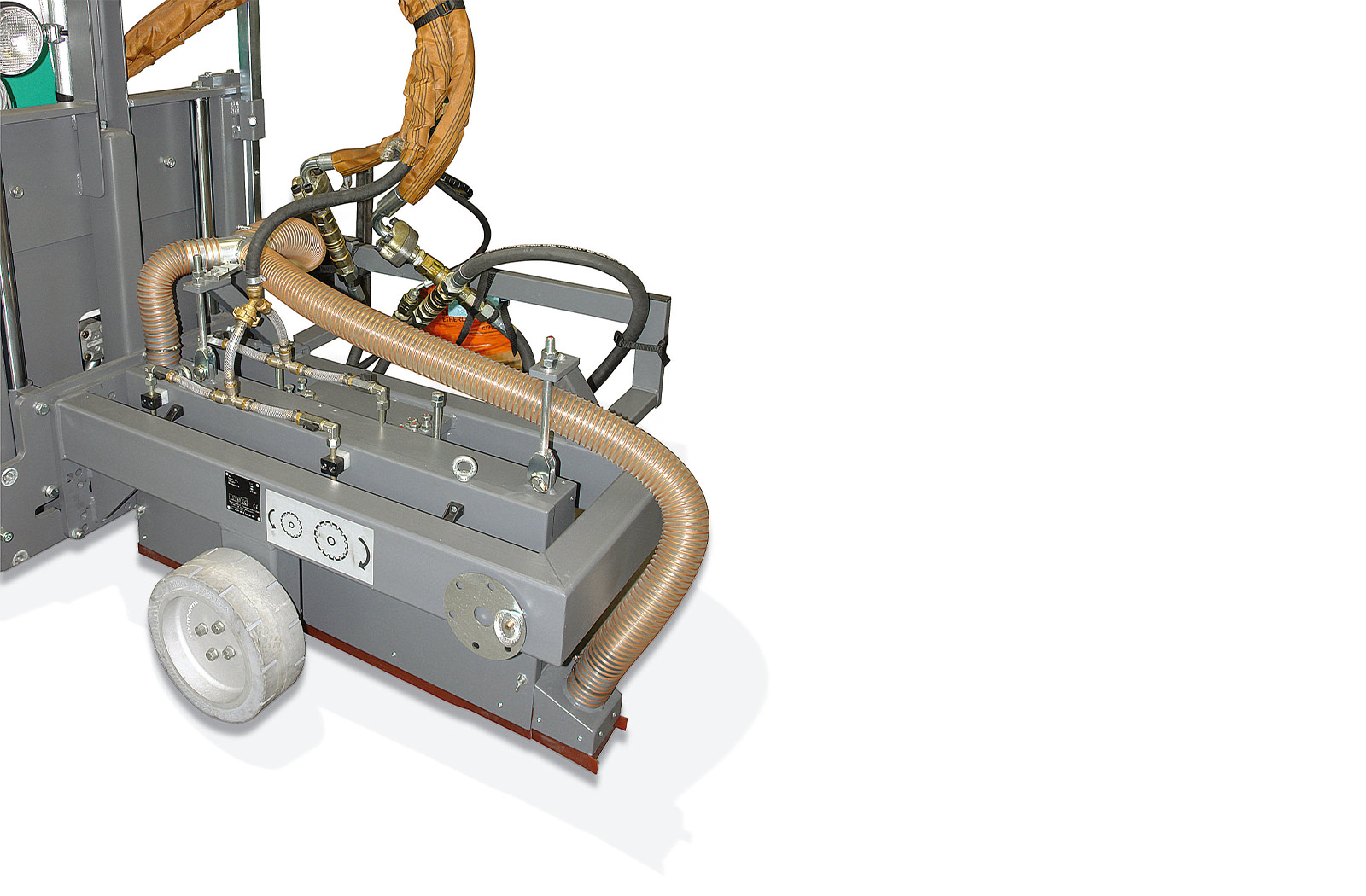

The ride-on joint cutter is the first choice for the most demanding projects in road construction, renovation, demolition and repair work. The performance and reliability of the high-performance diesel floor saw is unmatched when cutting asphalt and concrete, cutting fresh concrete and making separating cuts in asphalt and concrete. The hydraulic wastewater suction ensures a clean result during the cutting work.

The first-class ergonomics enables fatigue-free joint cutting over many hours. The operator controls the powerful machine easily and precisely using a joystick. The high-traction all-wheel drive distributes the drive power to all four wheels and ensures reliable propulsion. When turning a corner, the all-wheel drive switches off automatically, controlled by the steering angle. Travel drive and saw blade speed can be regulated electro-hydraulically, which ensures the optimal cutting speed for the saw blade at all times. The user-friendly design allows several sitting positions and offers the best view of the cutting area in both push and drag cut operation. The diesel floor saw gains even more versatility through fully integrated optional accessories. Steering wheel, grooving unit, suction system and a drilling unit are some of the accessories that are available. Working together with professional users, LISSMAC has developed the UNICUT 600 for the highest demands in joint cutting. Find out more about the number one among diesel floor cutters:

Technical data

stepless electric regulation

Further information

- All-wheel drive machine

- Multifunctional joystick for ease of operation

- Electro hydraulic steering system

- Optimized hydraulic circuit for improved power transmission to the saw blade

- Drive motor and saw blade speed are electro-hydraulically controlled for ideal saw blade cutting speed on various applications

- All-wheel drive optimally distributes power to all 4 wheels during operation. In turns, all-wheel automatically shuts itself off due to the steering angle.

- Optimal weight distribution due to low center of gravity

- Large fuel tank for reduced downtime

- Quick changeover from left to right-hand cutting – can be pivoted by 180°

- Large, non-marking drive wheels

- Stepless hydraulic height adjustment of the blade guard, independent of saw motor

- Saw motor with saw blade and blade guard can be moved sideways by 100 or 200 mm, as well as up and down by 150 mm

- Compact and user friendly design, suitable for pushed as well as pulled cuts, adjustable seating position

- All settings are controlled via the display on the centrally located operating panel, which also displays the engine parameters

- Easy access for routine maintenance work (air filter, battery, oil and fuel filter)