UNICUT 610

The number one amongst the diesel floor saws. Fully hydraulic, comfortable, easy to use with joystick control. Developed together with professional users for the most demanding applications.

The 100 kW / 136 PS powerful UNICUT 610 is the flagship diesel floor saw. Its hydraulically controlled drive is extremely robust even in the toughest of continuous use tasks and, can be operated without restriction under full load, without any significant wear. The fully hydraulic floor saw achieves cutting depths of up to 630 mm with saw blades up to a maximum of 1,500 mm diameter.

The ride-on floor saw is the first choice for the most demanding projects in road construction, renovation, demolition and repair work. The performance and reliability of the high-performance diesel floor saw is unmatched when cutting asphalt and concrete, cutting fresh concrete and making separating cuts in asphalt and concrete. The hydraulic wastewater suction ensures a clean result during the cutting work.

The first-class ergonomics enables fatigue-free joint cutting over many hours. The operator controls the powerful machine easily and precisely using a joystick. The optionally selectable all-wheel drive distributes the drive power to all four wheels and ensures reliable propulsion. When turning a corner, the all-wheel drive switches off automatically, controlled by the steering angle. Travel drive and saw blade speed can be regulated electro-hydraulically, which ensures the optimal cutting speed for the saw blade at all times. The user-friendly design allows several sitting positions and offers the best view of the cutting area in both push and drag cut operation. The diesel concrete and asphalt saw gains even more versatility through fully integrated optional accessories. Steering wheel, grooving unit, suction system and a drilling unit are some of the accessories that are available. Working together with professional users, LISSMAC has developed the UNICUT 610 for the highest demands in joint cutting. Find out more about the number one among diesel floor saws:

Technical data

Further information

- Multifunctional joystick for extremely simple operation

- Optimized hydraulic circuit for improved power transmission to the saw blade

- Electro-hydraulically controlled drive motor and saw blade speed for ideal saw blade cutting speed on various applications

- With the optional all-wheel drive, the power is optimally distributed to the 4 wheels and provides propulsion. When going around corners, the four-wheel drive switches off automatically based on the steering angle.

- Shortened wheelbase – smaller turning circle

- Optimal weight distribution due to low center of gravity

- Large fuel tank for reduced downtime

- Quick changeover from left to right-hand cutting – can be pivoted by 180°

- Large, non-marking drive wheels

- Stepless hydraulic height adjustment of the blade guard, independent of saw motor

- Saw motor with saw blade and blade guard can be moved sideways by 100 or 200 mm

- In addition, the height of the slide box can be adjusted by 150 mm.

- Compact and user friendly design, suitable for pushed cuts as well as pulled cuts

- Adjustable seating position

- All settings are controlled via the display on the centrally located operating panel

- Easy access for routine maintenance work (air filter, battery, oil and fuel filter)

Attachments:

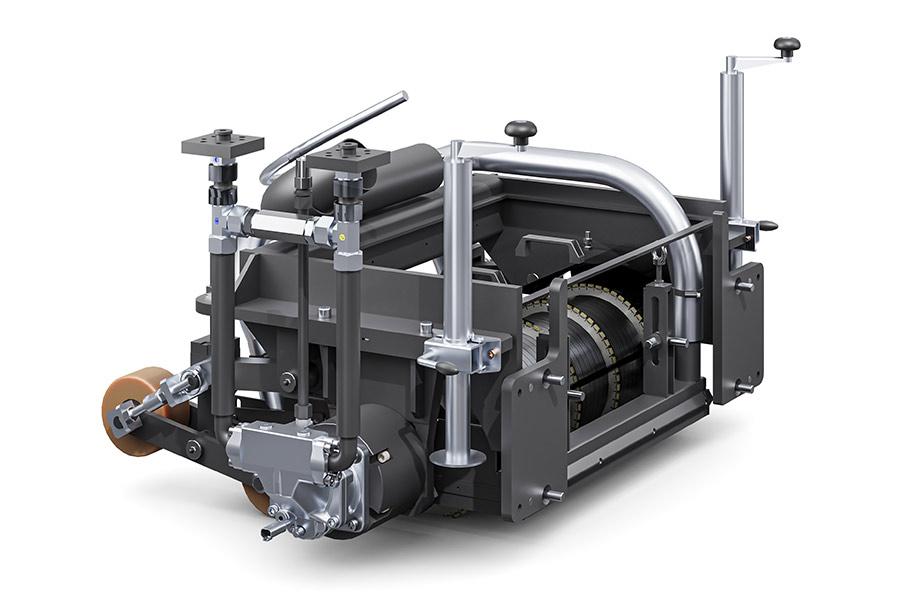

Grooving unit

Grooving includes the creation of surface textures or the cutting of grooves in traffic areas. In addition to improving grip and evenness, reduction in the risk of aquaplaning and lower noise levels are further advantages that should be emphasized. With a working width of 600 mm, the LISSMAC grooving unit is ideal for small and medium-sized areas.

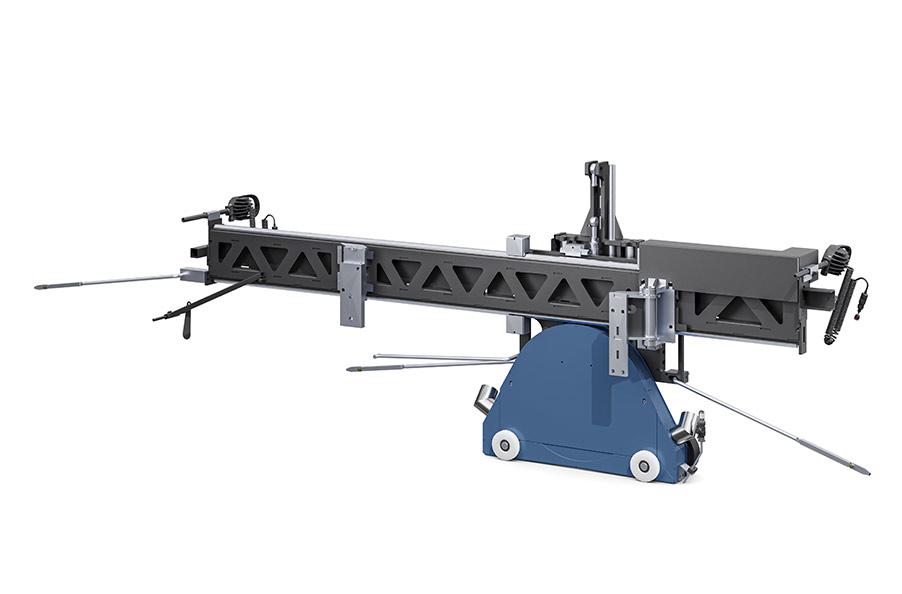

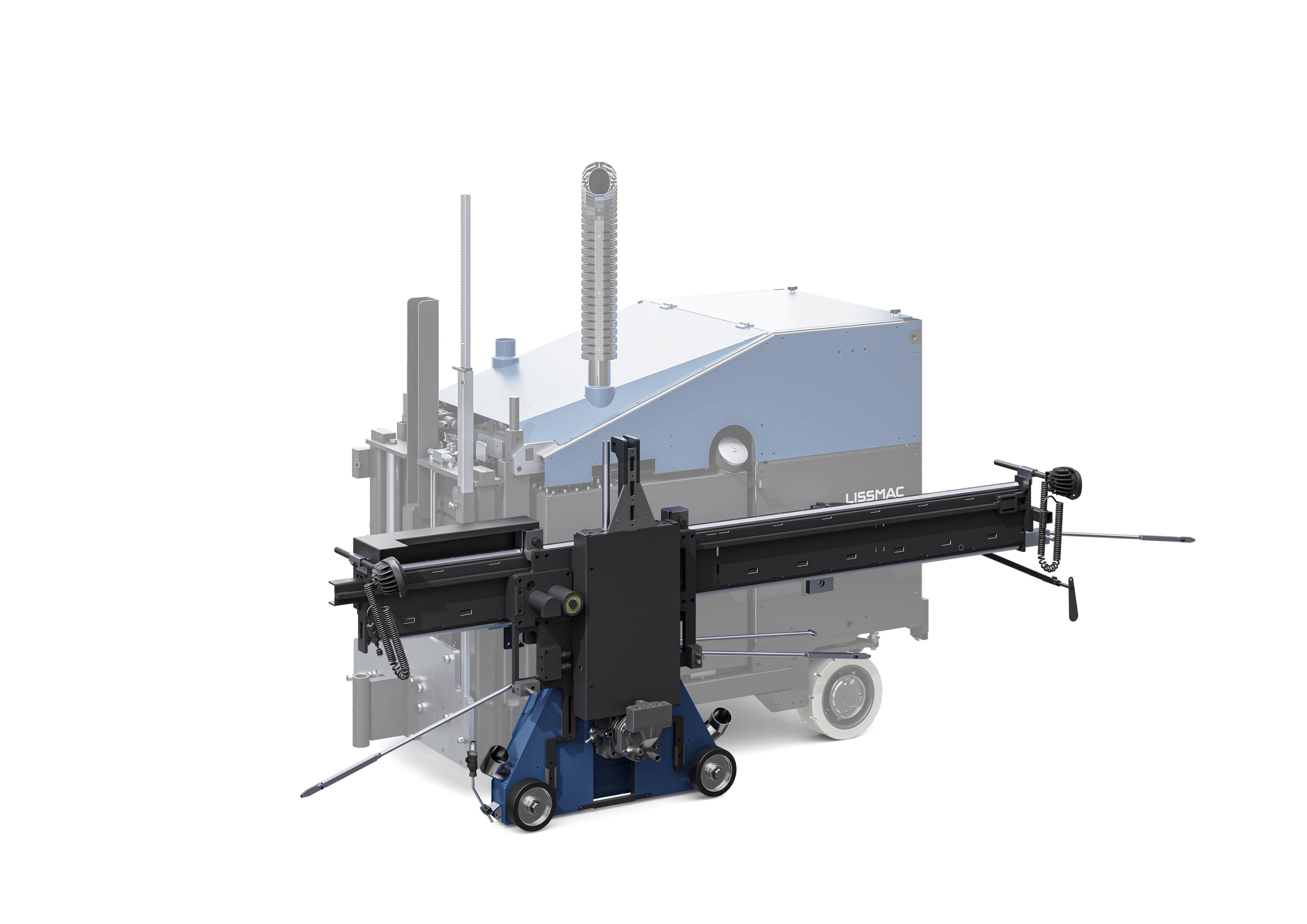

Side cutting unit

The side cutting device is mounted on the side of the machine and is used primarily for cutting transverse joints on freshly created concrete road surfaces (dummy joint for the targeted localization of cracks). A track system allows the saw drive to move across the full wheelbase and beyond. This means that the entire roadway width can be cut in one operation without time-consuming maneuvering and multiple setting-up of the floor saws.

Drilling unit

One of the main applications of the drilling unit is the installation of runway and taxiway lights at airports. Holes are drilled in runways and taxiways, ready for installation of the lights. With our drilling unit, users can carry out core drilling in traffic areas up to a diameter of 600 mm.

Tandem cutting unit „TLA“

Longitudinal and expansion joints are ideal applications for the tandem longitudinal cutting attachment. Two saw blades of different diameters are arranged one behind the other in a line, whereby the front, smaller saw blade opens the joint and the desired depth of the joint is achieved with the rear, larger saw blade with a finishing cut. The cutting method is pulling (drag cut).

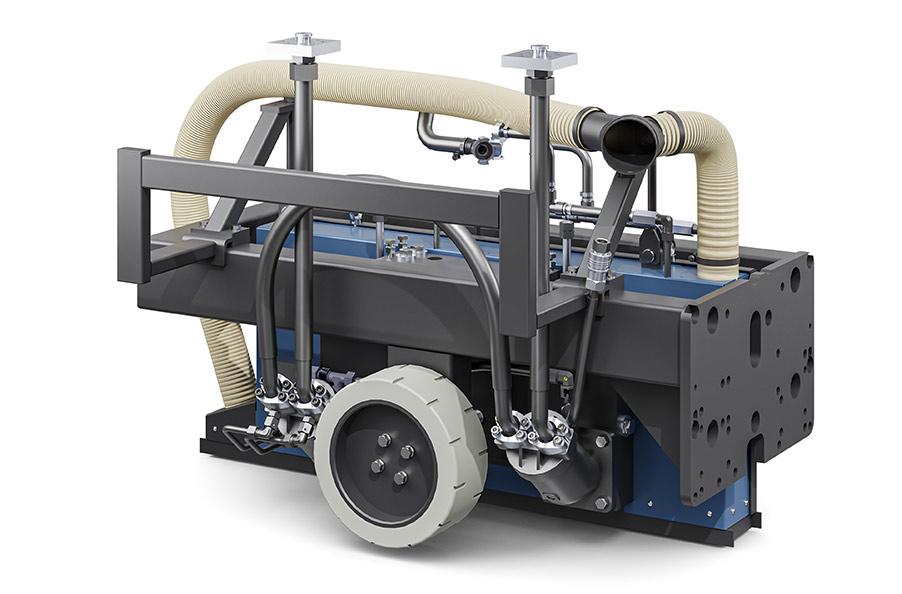

Wet suction unit VACUUM WET 500

- All parts can be quickly removed for cleaning

- Simple emptying of the wet container using eccentric lever

- Wet container with fine hole Ø 5 mm sieve easy and quick to clean

- Sieve made completely of stainless steel (service life)

- Compact design with high ground clearance

- Closed system that is directly installed on the floor saw and driven by a hydraulic interface to the machine