DTS 1000

The long-lasting XL solution for demanding professional users. The all-rounder for every construction site impresses with the latest technology and user-oriented construction.

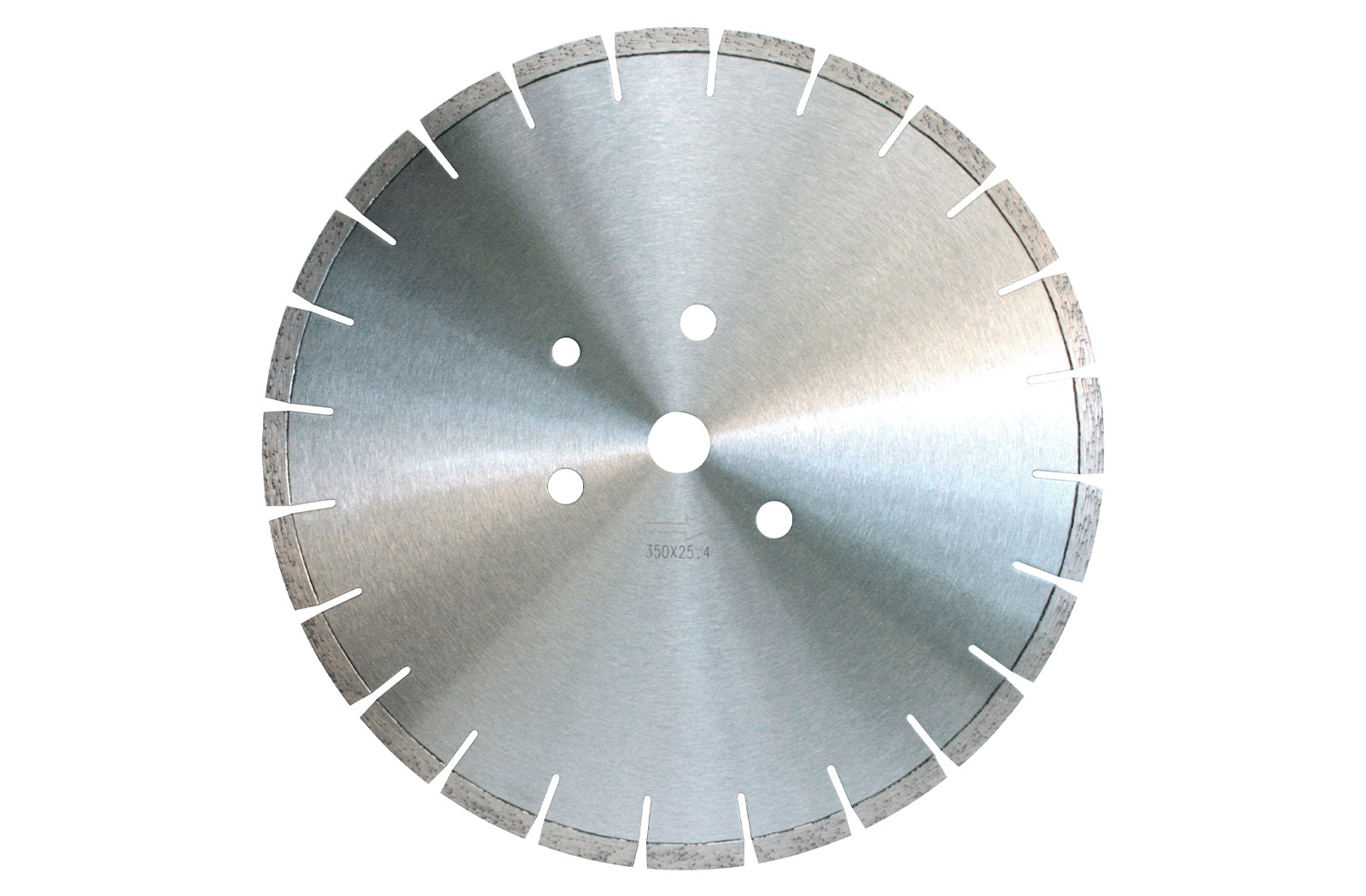

State-of-the-art technology and user-oriented design make the DTS 1000 diamond cutting saw the all-round saw for daily, demanding use. The site-specific and low-maintenance construction guarantees operational reliability and high values. The stone saw cuts up to 420 mm deep with 1,000 mm saw blades (standard 920 mm) (370 mm) deep. The maximum cutting length is 660 mm. The powerful 7.5 kW 400 V motor ensures high cutting performance, with an optimal working speed of 910 rpm. Instead of one If V-belts which are is susceptible to wear, the stone saw works with a chain drive in a completely closed and low-maintenance gearbox. The blade feed is either by hand (DTS 1000 H) or by crank (DTS 1000 V).

The diamond cutting saw is designed for tough use in building construction. When trimming masonry and sand-lime bricks the innovative sawing technology and the precision saw head ensures an accurate cutting path and low blade wear. The optimal water supply system ensures extremely efficient saw blade cooling and guarantees the immediate removal of the saw debris. The stone saw has an extremely stable and resilient frame, the three-point support results in a safe, torsion-free stand.

The diamond saw makes daily work easier thanks to its user-friendly design and front located controls. The saw table with embossed scale is galvanized for a long service life. The table guides and castors are durable high-strength, low-wear steel. The front swivel castor enables an effortless, quick relocation of the stone saw on the construction site. The forklift lugs and lifting eyes speed up and simplify transport. The saw head can be easily moved to a safe transport position. LISSMAC knows what professional users need. The DTS 1000 diamond cutting saw impresses with a wealth of practical details. Get to know the all-rounder better:

Technical data

Further information

- Low-maintenance construction fit for the building site

- Excellent stable value and operational reliability

- Exacting table layout for precision stone cutting

- Fixed, distortion-free three point stability

- Stable and resilient frame

- Galvanised sawing table with imprinted scale

- Table guidance profile and rollers made of durable, high-strength steel

- Low equipment costs due to precise table guidance

- Perfect saw blade cooling and immediate removal of sawing debris with the optimum water feed system

- Easy to use and operate due to flexible loading and control elements in front

- Easy removal of the water pump (e.g. for cleaning or to avoid freezing)

- Water bath removable from the rear

- Saw head is easily positioned for safe transport

- Ease of manhandling with the front swivel roller, forklift pick-up points and lifting eyes.

- Saw blade drive via a high performance chain in a totally enclosed low maintenance gearbox – no v-belts – no wear