Ejection Unit

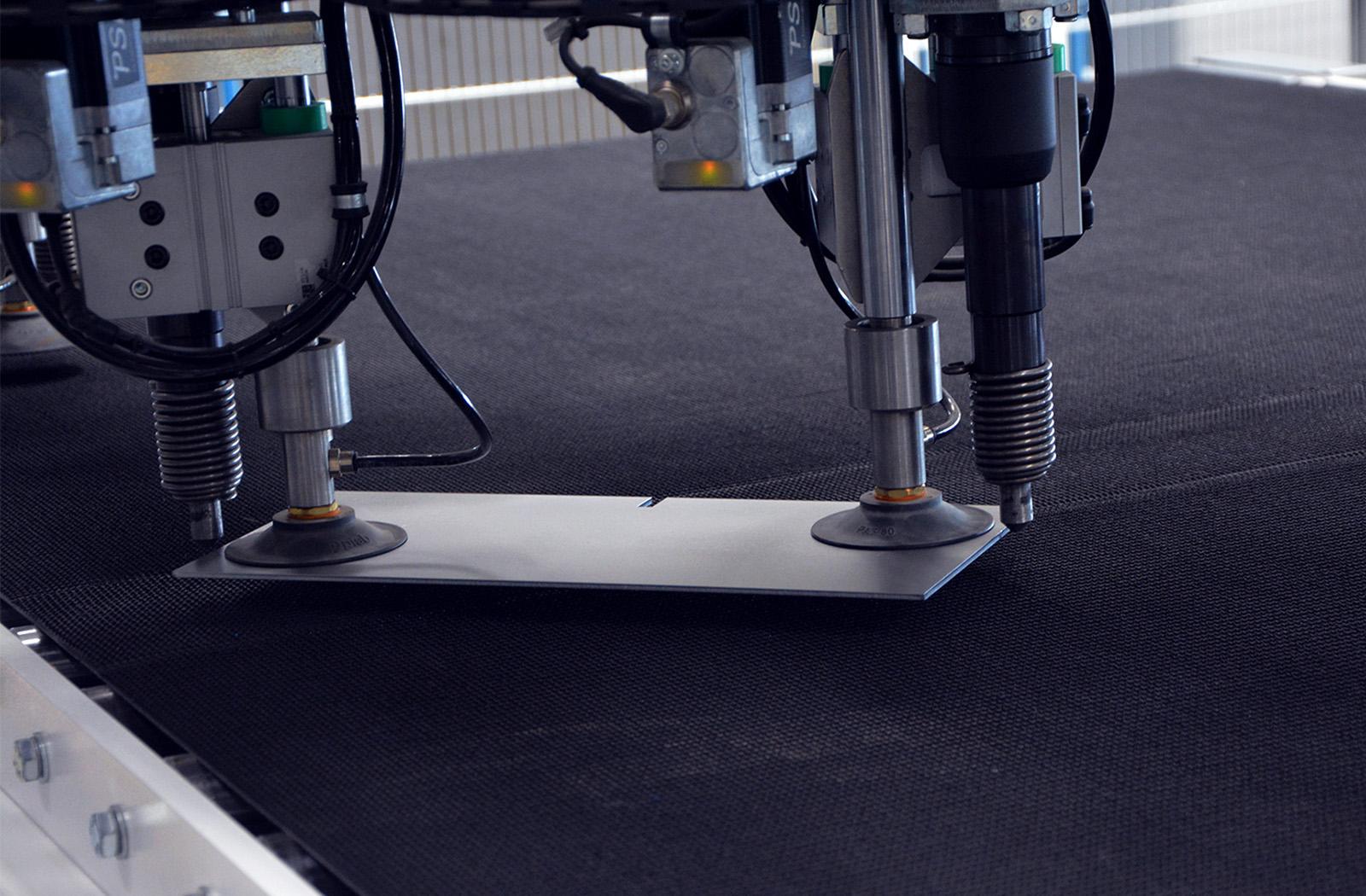

Automated sheet handling and ejection of components after the laser cutting process using a vacuum gripper and pneumatic handling.

The automated ejection unit enables precise and efficient removal of sheet metal components that were previously cut using a laser cutting process. The parts are knocked out of the scrap skeleton with pneumatic hammers and transported safely to the deburring machine for further processing using a vacuum gripper. The components are held in the blank with micro or nano bars. The system does not require optical image processing as it is based on the geometry data of the cutting plan and automatically determines the required number of suction pads. It can be flexibly adapted to different sheet sizes and thicknesses. Thanks to the balancing technology, the weight of the components is continuously monitored so that potential deviations are detected at an early stage and process errors are avoided. This innovative solution offers maximum flexibility and reliability in the handling of sheet metal parts with a high degree of automation, which relieves the burden on specialist companies in the long term. The ejection device can also be retrofitted to existing cutting systems or high racks and can be used regardless of the manufacturer. Only the interface needs to be adapted for the respective laser manufacturer

Contacter le service commercialDonnées techniques

Informations complémentaires

- Automation of time-consuming manual clearing of laser-cut components

- Automated transport: vacuum gripper system for precise and safe transport of sheet metal parts of different sizes and thicknesses.

- Flexibility: Supports sheet metal parts from DIN A4 to Euro pallet format with sheet thicknesses of up to 8 mm.

- Material independence: Vacuum gripper can be used with different materials without adaptation.

- Integrated fault detection: balancing technology monitors the weight of the components and detects deviations at an early stage.

- Efficient processing: No optical image processing system required, as geometry data is taken directly from the cutting pattern.

- Complete in-house development: From the gantry system to the process sequence to the knock-out station, developed for maximum efficiency.

- Customer-specific adaptations: Flexibility in the integration of different machines and software solutions.

- Reliable residual grid disposal: Separate station for the collection and removal of residual grids.

- Buffer storage: process stability thanks to a buffer storage unit, decoupling from the laser cutting process

- Saved personnel capacity: high level of automation results in little manual intervention