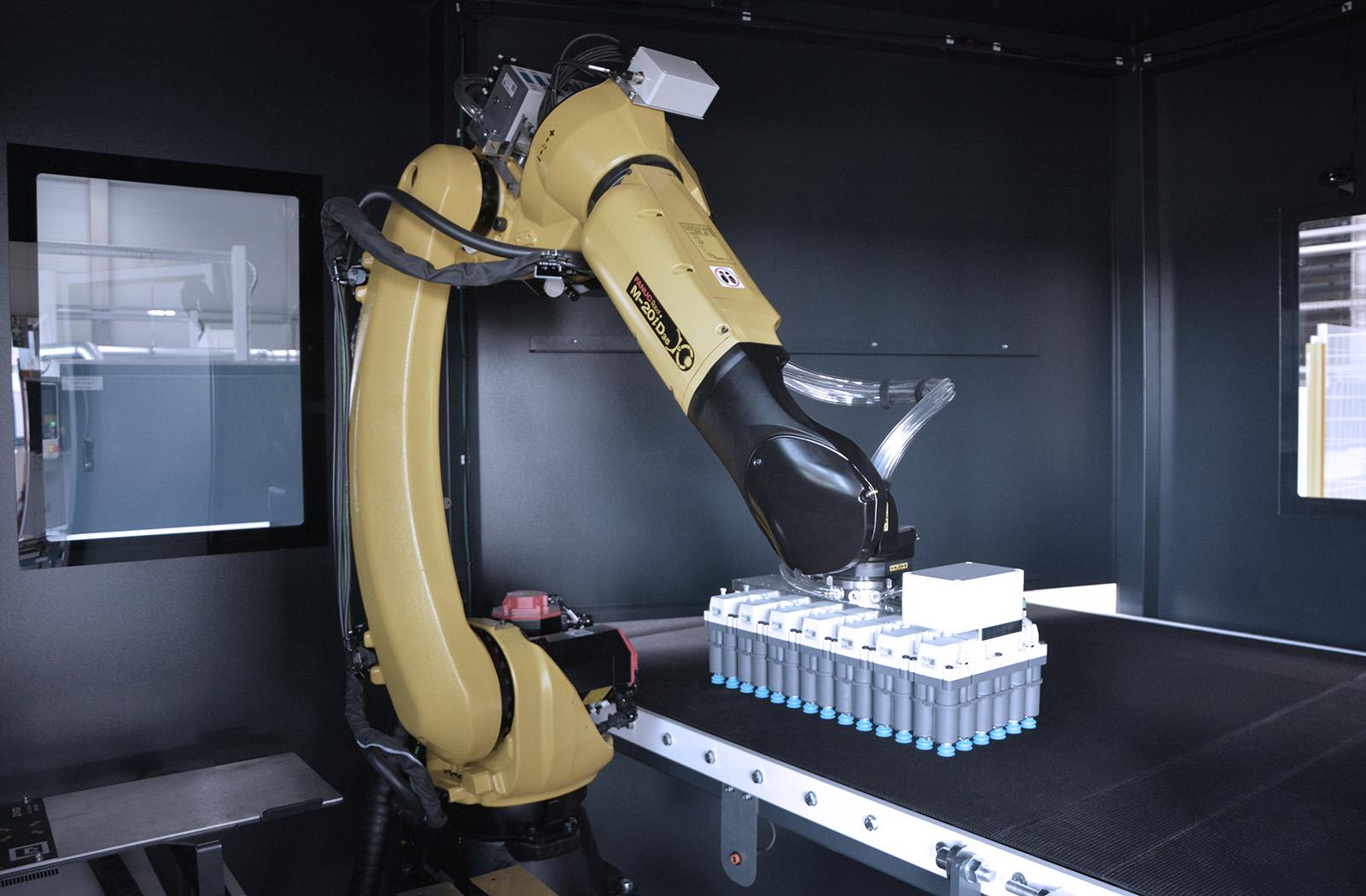

Automation unit

Robot cell for automated loading of components onto deburring machines thanks to innovative AI software and 3D part recognition

The compact deburring cell from LISSMAC, developed in collaboration with J. Schmalz GmbH, offers a fully automated solution for sheet metal processing. Equipped with the ivOS Solution Kit Sheet Metal from Schmalz, consisting of AI software, intelligent gripper technology and 3D vision sensors, the system automatically recognizes sheet metal parts and generates the robot movements independently, without any programming knowledge. Thanks to the flexible gripper control, parts of different geometries can be handled reliably. The cell works efficiently with stacked or individually fed sheet metal parts and transports them to the deburring system. Alternatively, large or heavy components can be inserted manually via a side flap.

LISSMAC supplies the complete solution including housing, conveyor technology and deburring system. This automation solution reduces manual workload, increases efficiency and enables flexible integration into existing production processes. It ensures the economical use of robot technology, even with small batch sizes and a high variance of shapes and sizes (high mix - low volume). Ideal for companies that want to maximize productivity and precision.

Distribuzione dei contattiDati tecnici

Ulteriori informazioni

- Solution Kits ivOS Sheet Metal: Flexible system for automatic detection and handling of different sheet metal parts in order to load deburring and grinding machines.

- AI robotics: System continuously learns and optimizes, automates approx. 95% of the parts spectrum

- State-of-the-art robotics technologies such as AI software and 3D vision software for precise handling and automation

- Plug & play, no expert knowledge or programming required, tested and approved

- Modular automation kit: Customizable solutions for different customer situations, including special solutions.

- Robotic and gripping solutions for different part spectrums, e.g. weight, geometry and dimensions.

- Sheet separation: Robot only lifts individual sheets thanks to intelligent control, double-blank detection and the effect of peeling off, ensure the quality of the complete process

- Retrofit: retrofitting to existing machines possible

Reduce downtimes and error rates - Saved personnel capacity: high level of automation results in little manual intervention