Hairline Grinding with Wet Processing - New Wet Grinding Machine Enables Maximum Flexibility

Mei 19, 2021

Reliable Presentation of Hairline Grinding with Wet Processing

Lechmann Engineering stands for the highest quality in aluminium processing. Increasingly, the company also manufactures components for high-end audio equipment and lifestyle products as a supplier. In order to reliably ensure the required high quality in terms of surface feel and appearance, the Berlin-based manufacturer has now invested in a new wet grinding system.

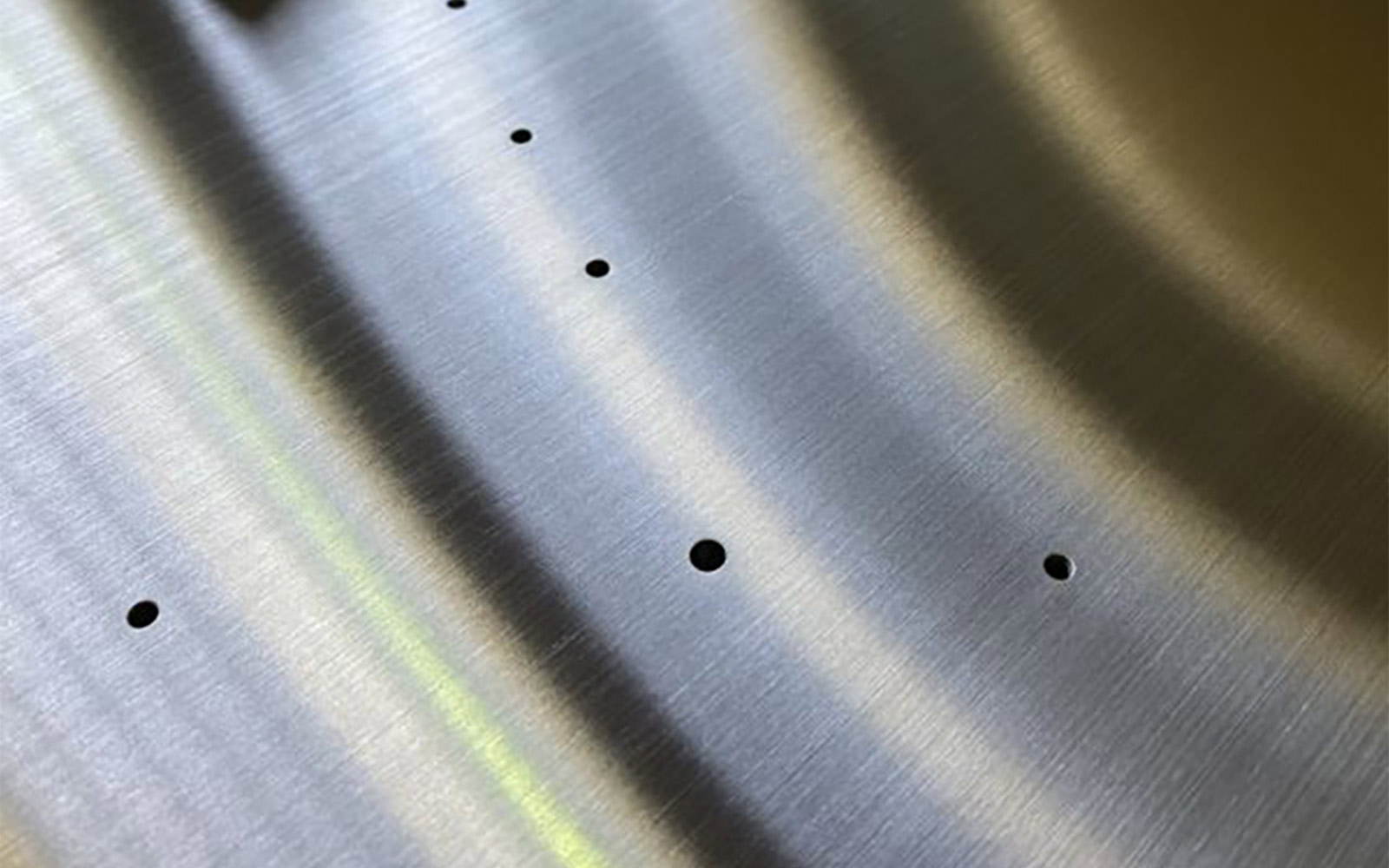

Aluminium components are often used in amplifiers, record players, loudspeakers and other audio equipment in the high-end segment. These not only look particularly elegant, but can also reflect the manufacturer's design specifications and emphasise the specifics of the product by means of an individual surface finish. This is precisely where Lechmann's expertise comes in. Aluminium processing across the entire process chain: Machining, forming, surface finishing and printing. However, what sounds so straightforward does indeed hold some challenges: High-quality aluminium grinding requires manual know-how, especially if it is to be followed by anodising.

"Grinding is a very decisive point for us with regard to customer requirements. We are known for highly decorative grinding in the high-end sector," says Ralf Behrens. He bought the company in 2007 and has acted as managing partner since 2015. He is also involved with the Chamber of Industry and Commerce and knows the importance of the valuable know-how of his employees. "Grinding is a craft that requires years of experience and good training for the employee. But unfortunately, the apprenticeship profession of grinder no longer exists," he explains. In training of surface coaters, the subject is only briefly addressed. So the company was looking for a solution that would help relieve the burden on employees. Of course, product quality and process efficiency should also be ensured.

A High-Quality Microsection is a Sign of Quality

"Against this background, we have been looking into the topic of grinding machines for some time. But it was clear to us that we could only maintain our quality standards with the right plant technology," says Christiane Marquardt. The graduate industrial engineer has been with the company since 2015, was initially responsible for plant management together with Matthias Balz and has been responsible for economic matters at Lechmann as an authorised signatory since 2020. Thus, Marquardt and Balz were together on the search for the right technical solution.

In 2016, they came into contact with LISSMAC Maschinenbau GmbH at a trade fair. Several approaches to a solution were considered. At first, the focus was more on dry machining. Simply to save the subsequent cleaning. "Of course, the result, i.e. the grinding pattern, is by far not as optimal with dry machining as with wet grinding, especially with grinding oil. However, since it is very important to us to present the hairline finish, we looked into the wet sanding technique from LISSMAC in 2019," says Marquardt, looking back, citing requirements for the decision-making process.

New Wet Grinding Machine Enables Maximum Flexibility

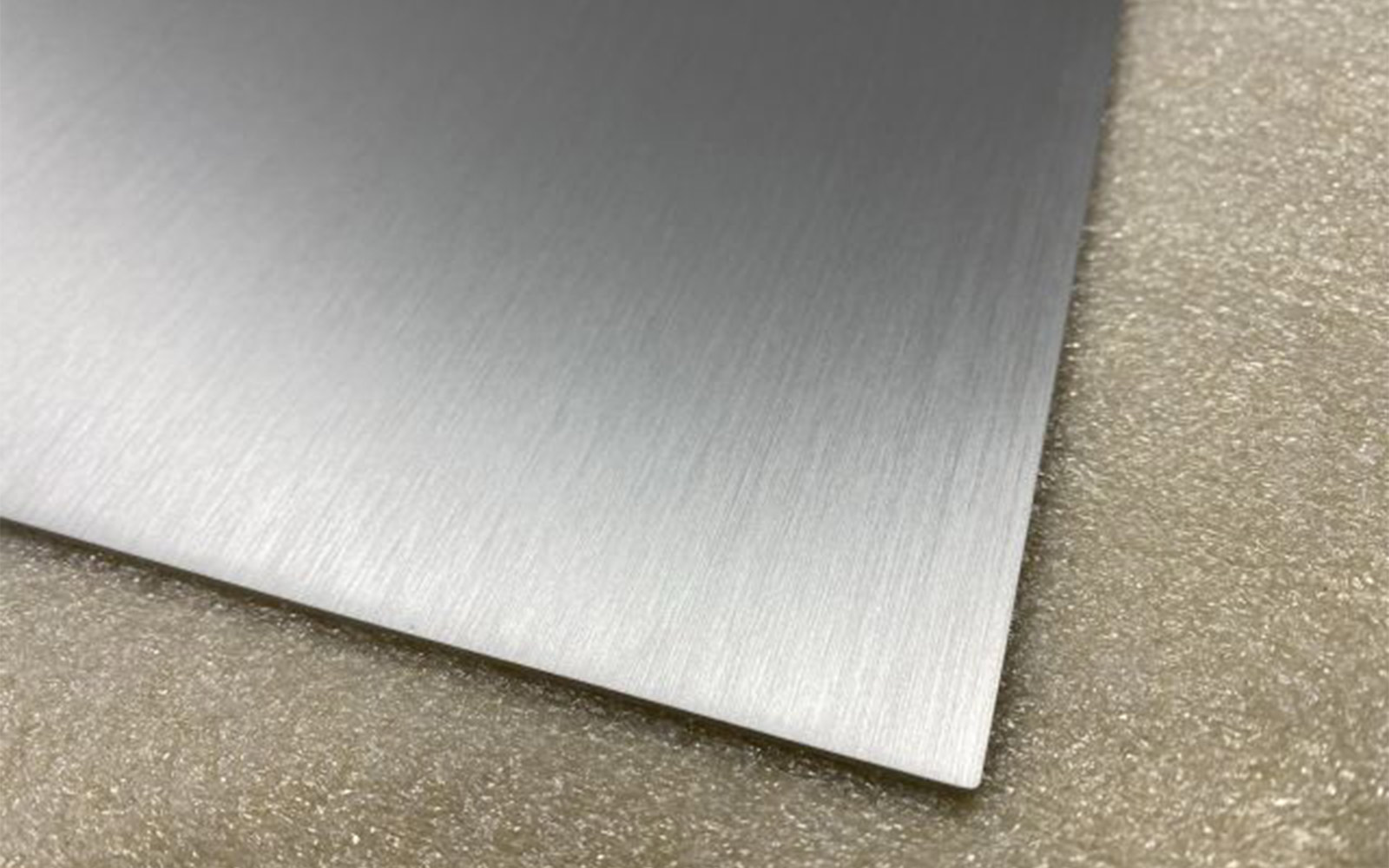

Lechmann Engineering then decided on an SMW 535 from LISSMAC -, a grinding machine that uses the wet grinding process to ensure optimum surface grinding. The machine is easy to operate via a touch-screen terminal and allows over 10,000 programmes to be stored. The abrasive belts can be changed within minutes. The system is also designed so that both belt types fit into the same unit. This brings great flexibility and allows many different applications with one machine.

Other features include a drying system, an integrated filter system, a conveyor belt control system and various safety features such as door switches on all doors, the safety safety edge and overthickness protection. The concept of the freely configurable SMW 5 series is based on a solid machine frame and allows the user to open the complete machine for easy and quick maintenance.

Several technical challenges had to be solved

Lechmann only processes aluminium in small and medium series. This means that the demands on the production technology also change frequently. With the SMW 535, many things are now easier.

For example, reclamping the abrasive belts for the different applications was always very time-consuming. Today, this is only set in the machine. "It is also important for us to grind suitable large-format sheets. Due to our large product variety, we also decide here when to use the LISSMAC technology depending on the number of pieces," says Christiane Marquardt. Managing director Behrens adds: "The new acquisition has also contributed to our portfolio expansion, as we can now offer classic industrial grinding. In addition, medium-format sheets can now be ground in one operation with the new SMW 535. And we can also deburr." This would relieve the physical strain on the employees. In the past, deburring was often done by hand, which was very strenuous. And at the end of the process, every part is checked, so the quality has to be right, "Behrens continues.

Extensive Tests Were Very Important

The very special product portfolio of Lechmann Engineering was also quite a challenge for the plant manufacturer LISSMAC. "It was necessary to configure a suitable plant that would meet exactly these needs. This required many discussions and tests to develop the optimal solution. We are quite proud that we managed to do this jointly," says Dirk Schürstedt, Area Sales Manager Metal Processing at LISSMAC Maschinenbau GmbH. Since the final processing result can only be seen after anodising, many test sheets were sent from Bad Wurzach to Berlin for assessment and anodising. It took about a year to work out the machine concept in detail and to implement it precisely. "It was important to proceed in such a concentrated manner. In the end, the result was a high-quality machine that was optimally tailored to the special requirements of the user," emphasises Schürstedt.

Plant technology Stands for Sustainability and Individuality

"The new plant was originally intended to be an automated plant that would integrate the machine stock to the greatest possible extent. Initially, I wanted to get closer to this idea. Simply to merge the existing techniques. Therefore, dry machining was also the first approach," he reflects. The new machine, however, is now a wet grinding machine that does not work with a water-oil-emulsion mixture, but with a pure grinding oil. This is cleaned in the process and reused again and again. And this not only means sustainability in processing. It also produces a very individual finish.

There is a great deal of individuality in the machine, which was configured and implemented precisely to meet Lechmann's production requirements. This applies to the grinding units as well as the grinding technology, the periphery or the output. And in addition, a reliable repeat accuracy within a defined corridor is ensured.

An important factor on this development path was aluminium, the material that Lechmann processes. "There are different aluminium compositions. There are definitely differences in quality, which are then ultimately reflected in the product. So we have to test in advance: the different types and compositions of aluminium used as well as the different grinding," says Behrens. Lechmann always uses quality material for its high-quality products. The question is: How does the aluminium behave during machining? The fact that machine builder LISSMAC took enough time for all the necessary tests was very important and positive for managing director Ralf Behrens. Because now the company definitely has a unique selling point on the market thanks to this very individual plant.

Suitable Framework Conditions were Created

The industrial grinding that Lechmann has to cover in order to continue to guarantee its quality reputation on the market is reliably realised by the new SMW 535 from LISSMAC. And the employees are also relieved, because the pre-grinding can now be done by the machine.

But it was also necessary to create the required space for the machine, because the machine had to be close to the grinding shop and should be integrated into the existing processes. In the end, spatial restructuring was the result. And media such as compressed air and the oil line in combination with cleaning had to be relocated accordingly. In addition, aluminium is highly explosive. Therefore, a central exhaust system was also installed during the reconstruction measures. The plant is now in-house explosion-proof.

Aluminium Machining for High-End Producers

"With wet grinding, we can guarantee our Lechmann quality. It is precisely this quality that is demanded by our customers in the market and that is exactly why the high-end producers come to us. With the new LISSMAC system, we can realise this quality," states Managing Director Behrens. And the employees are also satisfied with the new technology. "One of our grinders was quite sceptical at the beginning. But when he realised that his manual know-how is still in demand when using the new SMW 535, he was convinced. And in the end, the physical effort for the employees is much less," says Marquardt. And last but not least, the machine ensures easy adjustment of the complex grinding parameters.

The SMW 535 with the customised configuration was ordered in September 2020 and put into operation in December 2020. Since then, the wet grinding machine has already proven itself in many ways at Lechmann and is used for all parts with industrial grinding.

Text: Annedore Bose-Munde, Fachjournalistin für Technik und Wirtschaft, www.bose-munde.de