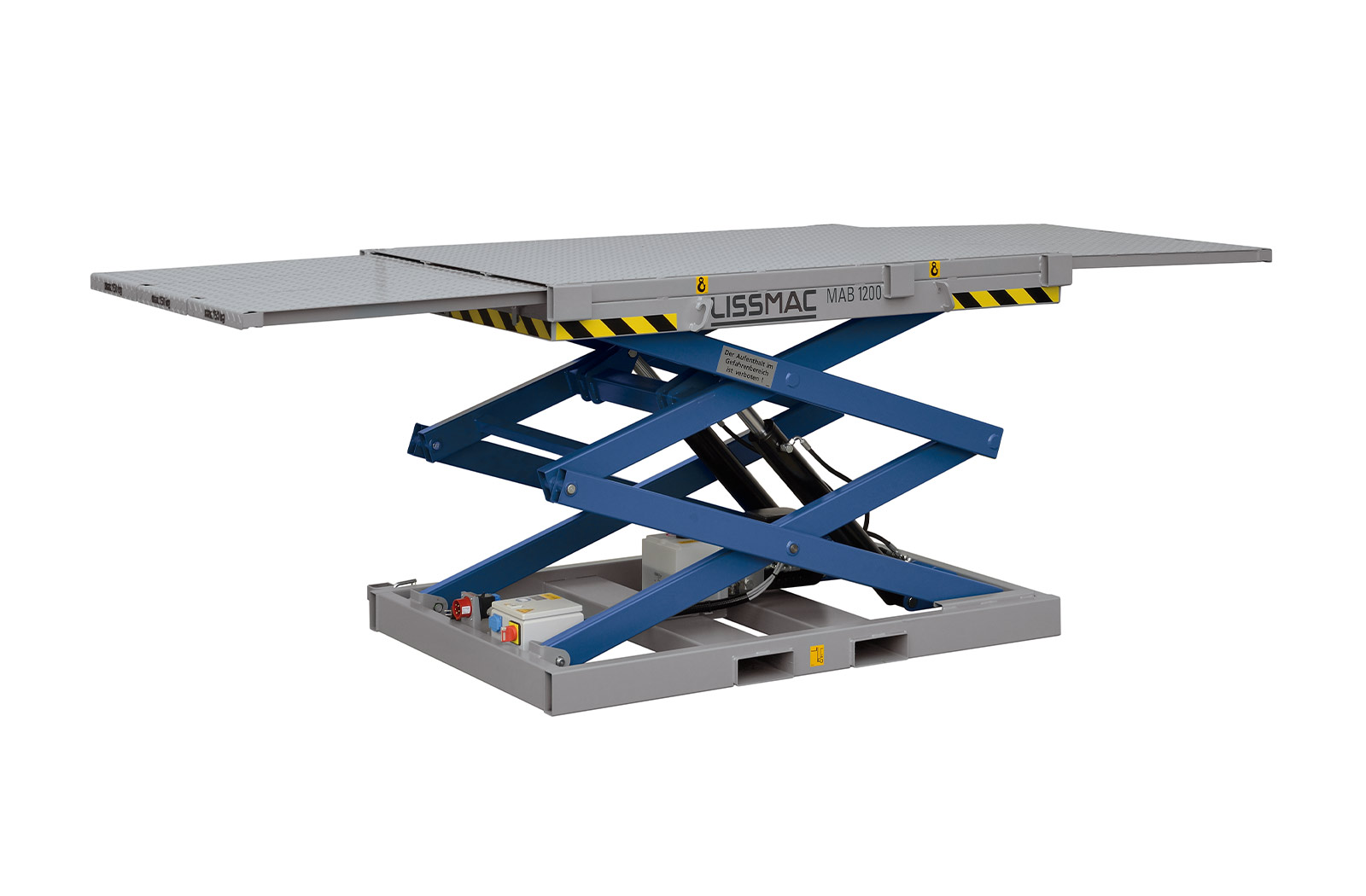

MAB 1200

Saves energy and money. The masonry work platform moves up as construction progresses, accelerating processes and reducing the workload. The ideal solution for house construction, industrial construction, structural engineering.

The masonry work platform MAB 1200 sets the standard for economy, cost savings and simple operation. The mini platform supports the masonry worker in both ergonomics and work processes. Thanks to its short set-up times, it is very flexible to use. The masonry work platform has a load capacity of 1,200 kg and is 1.85 m long (3.6 m with extendable walkways left / right), 1.32 m wide and reaches lifting heights between 0.48 and 1.99 m. The electric / hydraulic drive is fed with 230 V or 400 V.

The masonry work platform simplifies and accelerates masonry work in house building, industrial construction, building construction, renovation and formwork. Due to the base frame and the symmetrically arranged cylinder the platform achieves an optimal weight distribution and a constant load capacity over its entire lifting height. Side bulb extensions improve stability and give the best possible adaptation to the site conditions.

The non-slip checker plate covering on the work platform ensures a secure footing even in damp weather. The double-acting hydraulic cylinder has a safety valve which relieves hydraulic pressure during transport, benefiting longevity. A practical railing frame further improves the transport properties. The masonry work platform has a central electric switch box to enable additional platforms to be connected. The operation of the Masonry work platform is carried out by hand control device or foot switch. The masonry work platform accelerates processes and promotes ergonomic working by significantly reducing the workload in masonry construction. See the performance the MAB 1200 for yourself:

Technical data

Further information

- Minimal setup times - easy and quick assembly/disassembly of the working platform

- Optimum weight distribution due to the large supporting base frame and symmetrically arranged cylinders

- Optionally available wheel set for easy and quick moving of the platform – no point loading as the wheel set is placed above

- Constant load capacity over the entire lifting height

- Centrally located electrical control cabinet for adding additional platforms

- Optimum adaptation to construction site conditions via side bulb extensions

- Anti-slip chequer plate for a secure hold

- Double acting hydraulic cylinder with safety valve (Hydraulic release during transport)

- Railings can be easily transported using a railing rack

- Manual control device or foot pedal possible

We expressly point out that according to Machinery Directive 2006/42/EC, masonry work platforms may only be used with railings, without exception.